Introduction: Why Panel Technology Is the Backbone of TV Performance

In the rapidly evolving world of television displays, many buzzwords command attention—4K, HDR, Mini-LED, QLED—but behind the acronyms and features lies a quieter, fundamental component: the panel type. In LCD TVs, two dominant technologies determine how images form on-screen—Vertical Alignment (VA) and In-Plane Switching (IPS). While they are often considered from a marketing or user-experience standpoint, these two approaches are based on vastly different principles of physics, chemistry, and electrical engineering. Understanding how VA and IPS panels operate at the molecular and structural levels allows consumers, enthusiasts, and engineers alike to better appreciate why certain displays excel at contrast while others dominate in viewing angles and color consistency.

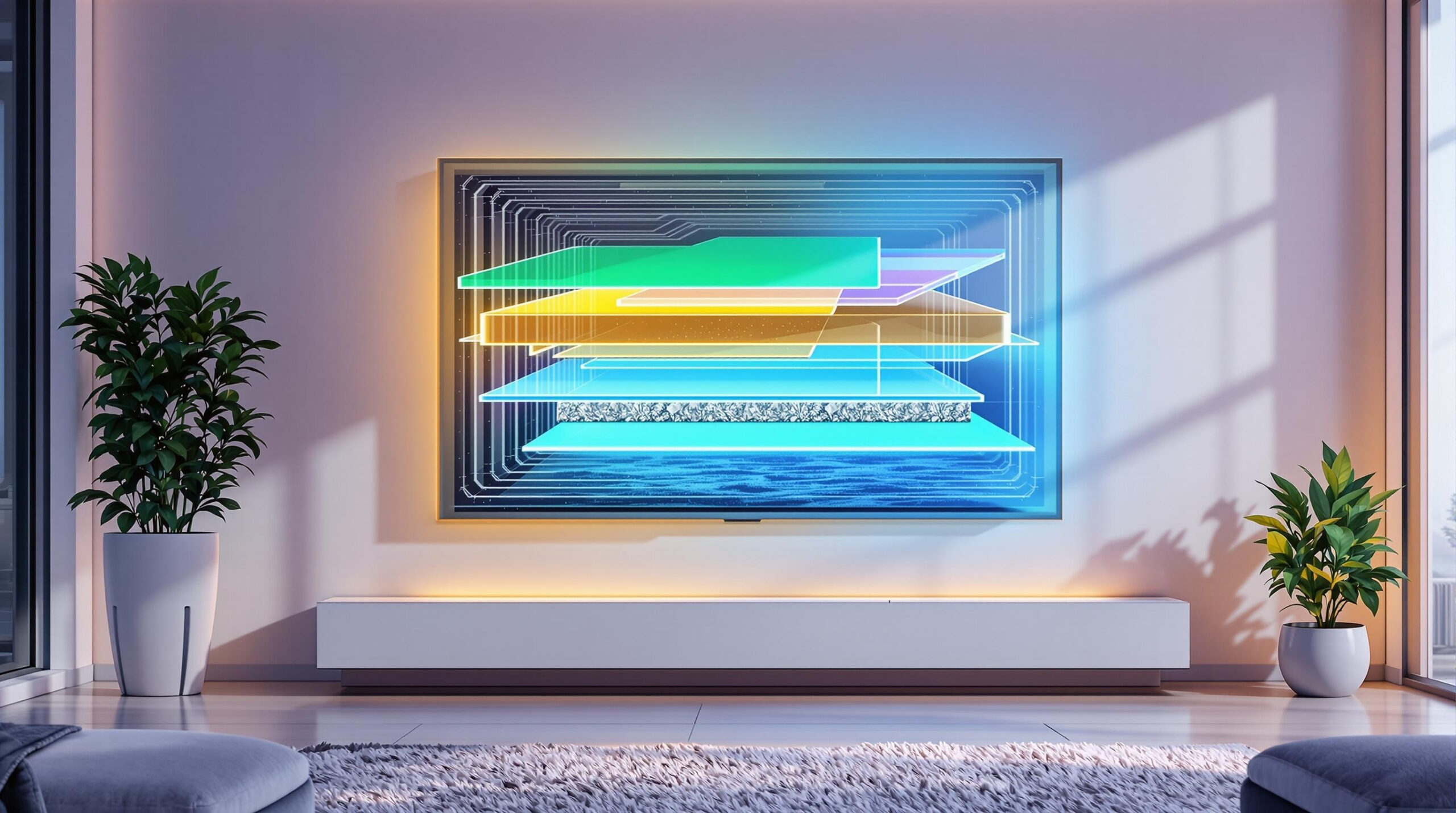

This article will take you under the glass—literally—to explore the scientific mechanisms of how VA and IPS panels work. We will delve into how liquid crystals manipulate light, how panel architecture dictates image performance, and how complementary technologies like LED backlighting and polarizer stacks integrate with these panel types. The goal is to decode the engineering behind your screen, making the invisible science visible without sacrificing technical accuracy.

The Core Technology: LCD as a Light Valve, Not a Light Source

To understand VA and IPS panels, we must first grasp how LCD technology functions at its core. LCD stands for Liquid Crystal Display, a technology that controls light rather than generating it. Every LCD screen operates as a light valve—its pixels modulate the amount and orientation of light that passes through from a backlight source. At the heart of this modulation lies a thin layer of liquid crystal material sandwiched between two polarizing filters and glass substrates.

Liquid crystals exist in a mesophase, a state of matter between solid and liquid. These rod-shaped organic molecules can reorient in response to electric fields, changing how they twist or align within their cell. By manipulating the orientation of these molecules, an LCD controls the polarization state of light passing through each pixel. The light itself comes from an external LED backlight, typically either edge-lit or full-array.

The difference between VA and IPS panels lies entirely in how these liquid crystals are aligned and how they react to electrical stimulation. These differences at the microscopic level dramatically influence key performance metrics such as contrast ratio, response time, color shift, and off-axis viewing.

VA Panels: Harnessing Vertical Symmetry for Deep Contrast

Vertical Alignment, or VA, refers to a method of arranging liquid crystal molecules perpendicular to the glass substrate when no voltage is applied. In the “off” state, the liquid crystals stand vertically, blocking the passage of polarized light. When voltage is applied, the molecules tilt away from the vertical axis but not entirely into a horizontal plane. Instead, they splay in various directions depending on the design, forming a configuration that allows light to pass through the color filters.

From a physics standpoint, the strong vertical anchoring of the molecules minimizes light leakage in the absence of voltage. This allows VA panels to achieve native contrast ratios often exceeding 4,000:1, as they can effectively block most of the backlight in dark regions of the image. This strong light modulation occurs because the molecular tilt path reduces phase distortion of the polarized light, which results in more complete extinction (blocking) of light when required.

VA panels also tend to have a simpler electrode structure compared to IPS panels, resulting in a high aperture ratio. This means more of the subpixel area can transmit light efficiently, which increases overall brightness at a given backlight intensity. VA’s architecture lends itself well to high dynamic range (HDR) displays where both peak brightness and dark detail are essential.

However, the directional orientation of the tilted molecules means that light transmission is highly dependent on viewing angle. As one moves off-axis, the angle between the viewer’s line of sight and the optical axis of the liquid crystals increases, leading to rapid changes in polarization interference. This causes reduced luminance and a shift in color perception, particularly in dark scenes.

IPS Panels: Maximizing Angular Uniformity with Planar Rotation

In-Plane Switching, or IPS, was developed to address the narrow viewing-angle limitations of VA and Twisted Nematic (TN) panels. Instead of standing vertically, liquid crystals in an IPS panel lie parallel to the glass substrates. When voltage is applied, the crystals rotate within their plane, maintaining a consistent molecular depth across the pixel while changing the polarization of the light.

This planar motion provides a crucial benefit: it maintains polarization alignment over a wider range of viewing angles. Because the crystals are rotating laterally rather than tilting into the third dimension, the optical path length remains more stable when viewed from the side. As a result, IPS panels can sustain color and brightness accuracy at angles exceeding 60 to 70 degrees off-center, making them ideal for large rooms or communal spaces.

Chemically, the liquid crystal mixtures used in IPS must be formulated to reduce viscosity while retaining anchoring strength at the surfaces. The alignment layers—usually polyimide films treated with rubbing or photo-alignment—must enforce precise initial orientations to ensure uniform in-plane rotation. The electric fields applied across each pixel are generated by a more complex interdigitated electrode layout, which creates a laterally directed field instead of the vertical field used in VA panels.

The trade-off for this angular superiority is lower native contrast. Since IPS crystals never adopt a truly perpendicular configuration, some backlight leakage occurs even when no voltage is applied. This leads to black levels that are higher (i.e., grayer) than those of VA panels. Typical native contrast ratios for IPS panels hover between 800:1 and 1,200:1 without local dimming.

LED Backlighting and Polarizers: The Unseen Partners in Panel Performance

Whether VA or IPS, every LCD panel relies on an external light source. Today, that source is overwhelmingly LED-based—usually white LEDs coated with blue-phosphor or used in conjunction with quantum-dot enhancement films. These LEDs sit either along the edges of the screen or in a matrix behind the panel, depending on the backlight type.

Light emitted by these LEDs first passes through a diffuser and optical film stack designed to ensure uniform luminance across the screen. It then enters the first polarizer, which filters out all but one orientation of light wave. The liquid crystal layer modulates this polarized light, and depending on how the molecules are aligned, the light either passes through or is blocked by the second polarizer on the opposite side.

For VA panels, the transition from vertical alignment to tilted alignment drastically alters how light is twisted through the polarization axis, creating the desired brightness modulation. In IPS panels, because the rotation occurs in the same plane as the substrate, the polarization rotation is smoother and more uniform across viewing angles.

However, polarizer quality and alignment precision are critical. Misalignments or poor extinction ratios (how well the polarizers block unintended light) can degrade contrast or cause light leakage. Manufacturers often add compensating films to improve off-axis performance, especially for VA panels, where contrast degradation is most severe off-center.

Response Times and Temporal Artifacts: The Fluid Mechanics of Motion

Another dimension of panel performance lies in how quickly the liquid crystals can switch orientations. This is governed by fluid dynamics, molecular torque, and elastic constants of the crystal mixture. VA panels often switch faster when moving from bright to dark states but slower when returning to brighter ones. This leads to asymmetric response behavior, which can cause ghosting or smearing in dark scenes.

IPS panels, due to their uniform rotation and lower viscous drag in-plane, often demonstrate more balanced gray-to-gray response times, particularly beneficial for fast-paced gaming or sports viewing. Engineers compensate for slower transitions in VA panels using overdrive circuits, which temporarily apply higher voltages to accelerate molecular motion. The downside of overdrive is potential overshoot, where pixels briefly exceed their intended brightness before settling.

High refresh rates, such as 120Hz or 144Hz, place additional stress on response times. Panel types must be carefully matched with backlight strobing or black-frame insertion to avoid image retention or visual flicker.

Color Gamut and Bit Depth: How Each Panel Reproduces the Visual Spectrum

Both VA and IPS panels benefit from quantum dot enhancement films that widen the color gamut beyond traditional RGB filters. However, the effectiveness of quantum dots depends on backlight uniformity and color filter precision—both influenced by the panel type’s aperture ratio.

VA’s simpler electrode layout allows more light to pass through each subpixel, enhancing color saturation and HDR highlights without excessive backlight intensity. IPS panels, due to their denser electrode matrix, often suffer from lower aperture ratios, which may necessitate stronger backlight levels to match brightness and color vibrancy.

Bit depth also plays a role. Modern panels often use 8-bit+FRC (Frame Rate Control) dithering or true 10-bit panels to display over a billion colors. Both VA and IPS architectures support this, but maintaining color accuracy depends on how well each pixel’s voltage is controlled—something IPS excels at due to its uniform electric field distribution.

Real-World Considerations: Viewing Conditions and Use Cases

In practical scenarios, the science of VA vs IPS becomes visible depending on use case and environment. VA panels dominate in home theaters and dark rooms, where deep blacks and punchy contrast matter most. IPS panels thrive in bright spaces or settings with wide seating arrangements, where color shift must be minimized.

Panel manufacturers have blurred the lines further. Some IPS variants, such as IPS-Black, use new materials and layering techniques to double contrast performance. Meanwhile, wide-angle VA panels now include advanced optical films that suppress color shift and luminance roll-off.

Ultimately, the underlying science remains—but engineering has adapted both panel types to new consumer demands.

Conclusion: Two Distinct Approaches, Both Pushing LCD Forward

At their core, VA and IPS panels represent two fundamentally different methods of manipulating light through liquid crystals. VA uses vertical-to-tilted molecular transitions to achieve high contrast and energy efficiency, while IPS uses lateral rotation to preserve color and luminance consistency across wide angles.

Understanding these differences through the lens of physics, chemistry, and engineering clarifies why each panel behaves as it does—and how innovations like Mini-LED, quantum dots, and AI image processing enhance their strengths while mitigating weaknesses.

As display technology continues to evolve, so too will the materials, alignment structures, and driving electronics behind both VA and IPS. But the essence remains: a delicate ballet of molecules, electrodes, and photons choreographed to bring moving images to life with increasing brilliance, accuracy, and intelligence.

LED/LCD TV Reviews

Explore Philo Street’s Top 10 Best LED/LCD TV Reviews! Dive into our comprehensive analysis of the leading OLED TV products, complete with a detailed side-by-side comparison chart to help you choose the perfect protection for your devices.