Resolution may capture headlines, but in QLED televisions it is the backlight that dictates how vivid the picture looks, how efficiently the set runs, and how long the panel lives. Every photon your eyes see on a QLED screen begins its journey in a sea of blue light. That light must be sculpted, filtered, and modulated with micrometre precision before it escapes as the vibrant reds, greens, and whites that make movies and games pop. This article uncovers the physics, chemistry, and electronic engineering that drive QLED backlighting—from gallium-nitride LEDs and quantum-dot nanocrystals to mini-LED arrays and real-time dimming algorithms—yet translates the science into plain language for enthusiasts who want more than marketing gloss.

The Blue LED Engine: Birthplace of Every Pixel

Modern QLED sets start with gallium-nitride LEDs that emit an intense royal-blue light centered around 450 nanometres. Blue photons carry enough energy to excite both red- and green-emitting quantum dots, making them the ideal “pump” colour. Engineers fabricate these LEDs on sapphire or silicon-carbide wafers using metal-organic chemical vapour deposition. The crystalline layers must be atomically smooth; any dislocations create non-radiative recombination centres that waste power as heat. To hit HDR brightness, manufacturers push currents to tens of amps per square centimetre, so the chips sit on high-conductivity substrates—often aluminium-nitride—bonded to heat spreaders that funnel thermal energy toward rear metal chassis plates. Keeping junction temperature below about 85 °C is vital, because blue diodes shift wavelength and lose efficiency as they warm, compromising downstream colour purity.

Quantum-Dot Conversion: From Blue to Billion-Colour

Directly above the LED array lies a polymer film sprinkled with semiconductor nanocrystals five to eight nanometres wide. At that scale, quantum mechanics squeezes the electron energy gap: smaller dots glow green, larger dots glow red when a blue photon excites them. Because each dot’s size dispersion is held below five percent, the emitted spectra are extremely narrow—roughly 25 nanometres full-width-at-half-maximum—three times purer than conventional phosphors. Narrow red and green peaks mean the TV can reproduce nearly every colour in the Rec. 2020 standard without spilling light into neighbouring channels. Chemists typically build indium-phosphide or cadmium-free zinc-selenide cores wrapped in zinc-sulfide shells, then laminate the film between moisture-barrier layers. That inorganic heart grants QLEDs a lifetime advantage: spectral shift stays under two nanometres after 50 000 hours of use, so hues remain accurate long after organic OLED emitters would have drifted.

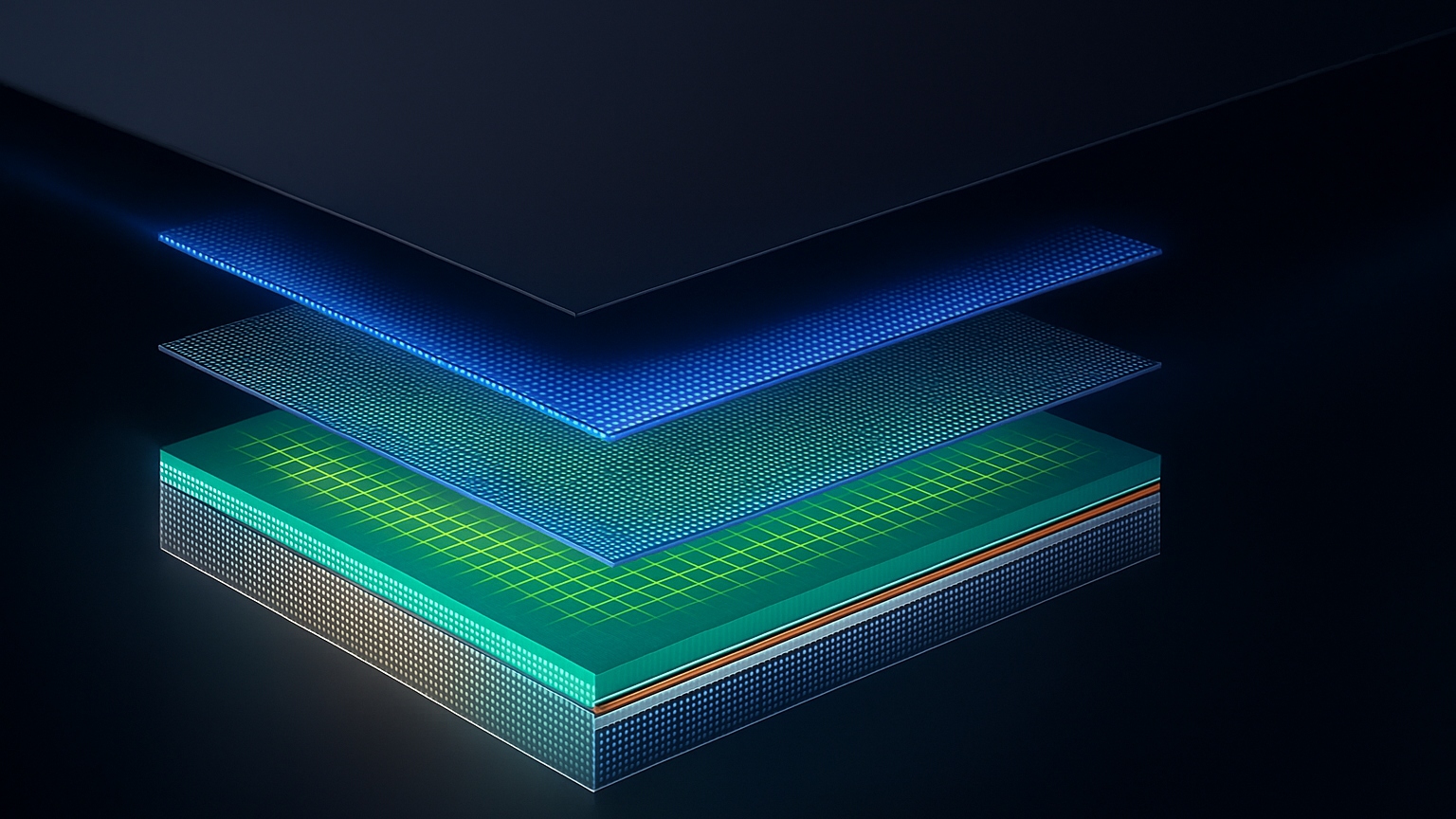

Optical Stack: Lenses, Diffusers, and Polarizers

Blue light and its quantum-dot offspring must be steered through a stack of optical sheets before reaching the liquid-crystal shutter array. First, a diffuser plate scatters light to erase hot spots from the discrete LED sources. Next, a prism sheet corrals photons into a narrower cone, boosting on-axis brightness by up to 40 percent. Engineers may layer a second diffuser above the quantum-dot film to ensure colour mixing is uniform at the sub-millimetre scale, preventing mottled reds or greens. Above these sheets resides the liquid-crystal matrix—a grid of thin-film-transistor gates that twist nematic molecules, acting like billions of microscopic Venetian blinds to modulate intensity pixel by pixel. Finally, an anti-reflection coating etched with moth-eye nanocones suppresses ambient glare, so colour and contrast stay true in daylight.

Full-Array and Mini-LED Backlights: From Floodlight to Spotlight

Older edge-lit LCDs placed LED strips along panel borders and relied on light guides to illuminate the screen. Brightness was decent but uniform; blacks looked gray because the entire backlight shone even when most pixels were dark. Full-array local dimming (FALD) moved hundreds of standard LEDs behind the LCD layer so groups of diodes—called zones—could brighten or dim independently, deepening blacks and sharpening highlights. The leap to mini-LED shrank chips below 200 micrometres and elevated zone counts into the thousands. Each zone is wired to a constant-current driver that can ramp from zero to full in milliseconds, allowing real-time adaptation to movie frames. More zones mean narrower halos around bright objects, cutting blooming and letting peak luminance soar past 2 000 nits without raising the whole screen’s backlight.

Local Dimming Algorithms: Software Shapes the Light

Hardware is only part of the story; sophisticated algorithms choreograph zone behaviour. The television’s image processor analyses incoming frames, predicts the brightest and darkest regions, and sets LED currents accordingly. It must also compensate for the liquid-crystal layer’s response lag—often five to ten milliseconds—by delaying LED pulses so shutters are fully closed before zones dim. Failure causes “pumping” artefacts where black bars flicker. Recent sets harness machine-learning models trained on terabytes of video to refine dimming decisions scene by scene, boosting shadow detail in a dark alley while keeping headlights crisp. Some flagship TVs even reshape zone borders dynamically, clustering mini-LEDs around bright moving objects to minimise halos.

Thermal Management: Keeping Cool Saves Colour

Driving thousands of LEDs and quantum dots at kilonit brightness turns a QLED into a sophisticated heat engine. Excess heat accelerates blue-LED ageing and can brown quantum-dot films, narrowing colour gamut. Engineers combat this using graphite vapor-chamber heat spreaders and aluminium heat sinks. Finite-element modelling maps thermal gradients across the panel; regions that run hotter receive thicker thermal pads or extra ventilation slots in the rear cover. Firmware throttles maximum frame-average luminance if ambient temperature climbs or if on-board thermistors near the LED strips breach predefined thresholds. Smart power management ensures HDR specular highlights shine while the set remains within safety and Energy-Star limits.

Electrical Design: From Wall Socket to Photon

QLED driving electronics start with a high-efficiency power supply converting AC mains to multi-rail DC. A main 24-volt bus feeds dozens of buck converters, each tied to strings of series-connected LEDs. Constant-current sinks regulate zone intensity, using pulse-width modulation above 20 kilohertz to keep flicker invisible. Meanwhile, gate-driver ICs address millions of liquid-crystal pixels at 120 hertz for motion-smoothness. Signal integrity teams battle capacitive crosstalk and electromagnetic interference because millivolt errors in TFT voltages can shift gamma curves, subtly lifting blacks or crushing whites. Shielded flex cables and synchronous buck regulators minimise electrical noise that might translate into speckling or flicker on screen.

Viewing Angles and Optical Compensation Layers

Liquid-crystal shutters transmit light anisotropically, so colour and brightness fall off at oblique angles. Manufacturers insert compensation films—birefringent polymers whose refractive index varies with incident angle—to widen viewing cones. Some premium QLEDs add a quantum-dot on glass (QDOG) structure that moves the colour-conversion layer closer to the backlight, reducing angular colour shift. When combined with mini-LED local dimming, these optical tweaks maintain 80 percent of central luminance even 60 degrees off-axis, crucial for family sofas that wrap around the screen.

Environmental Impact: Cadmium-Free and Energy Smart

Early quantum dots used cadmium selenide, a heavy-metal compound restricted by European RoHS directives. Today’s mainstream QLEDs substitute indium phosphide or zinc selenide without sacrificing spectral purity. In power terms, QLEDs exploit narrow spectra to waste less light in colour filters, cutting energy use 10 to 15 percent versus conventional white-LED LCDs at the same brightness. Local dimming saves additional watts by darkening backlight zones in nighttime scenes. Over a five-year ownership cycle, a 65-inch mini-LED QLED can consume hundreds of kilowatt-hours less than a non-dimming predecessor—good for both the electricity bill and the carbon ledger.

Longevity and Reliability: Designing for Decades

Quantum dots are inherently more photostable than organic OLED emitters, but backlight reliability still hinges on diode robustness and thermal cycles. Manufacturers perform accelerated life testing at 125 °C to simulate 50 000 hours of use. Driver boards include redundant current paths so a single LED failure merely dims one zone rather than blanking a column. Firmware logs cumulative operating hours and automatically reduces peak brightness after about 20 000 hours to extend LED life, a practice borrowed from professional projectors.

Future Directions: Micro-LED and Electroluminescent Quantum Dots

Research labs are pushing beyond mini-LED to micro-LED arrays where each pixel has its own self-emissive diode. That architecture could eliminate the liquid-crystal layer altogether, ending issues of viewing angle and response time while retaining QLED-level colour via quantum-dot colour conversion. Parallel work in electroluminescent quantum-dot diodes aims to make each dot itself the light source, marrying inorganic longevity with per-pixel control. Challenges remain—uniform current injection, mass transfer of microscopic dies, and moisture sealing—but prototypes already reach 3 000 nits with Rec. 2020 coverage above 90 percent, hinting at a backlight-free QLED future.

Conclusion: Backlight as the Unsung Hero of QLED Brilliance

From gallium-nitride wafers and nanocrystal chemistry to mini-LED grids and AI-driven dimming code, the QLED backlight is a tour de force of multidisciplinary engineering. Its job is simple to state—flood the quantum-dot film with just the right light at just the right moment—yet exquisitely complex to execute when brightness, colour accuracy, energy efficiency, and longevity must all peak at once. The payoff is a television that can blaze at rooftop-sun intensities, plunge to midnight-sky blacks, and render the full spectrum of human-visible colour with scientific precision. Next time a QLED image wows you, remember: every pixel’s journey began in that meticulously sculpted backlight, the silent engine powering your window to the world.

QLED TV Reviews

Explore Philo Street’s Top 10 Best QLED TV Reviews! Dive into our comprehensive analysis of the leading QLED TV products, complete with a side-by-side comparison chart to help you choose the perfect protection for your devices.